Service for Cosmetics(general consumer goods, professional goods)

we provide our customers with high-precision logistics quality and logistics services.

At Sakata Warehouse, with more than half a century of logistics business expertise in cosmetics and toiletries industry, we have been cultivateing various know-hows.

Supporting the Pharmaceutical Affairs Law, we are confident in our ability to provide high-precision logistics services to our customers through the construction of a logistics information system that realizes labor-saving and high-quality logistics operations management, including piece picking, transportation and delivery management, as well as a unique cargo labeling system that is linked to the picking and inspection system and the transportation and delivery management system, to link the functions of shipping labels and transportation labels.

Also, our staff – specialists in cosmetics logistics business -support clients for their logistics innovation as the stance of their agent. We also provide operation outsourcing services to the clients using their assets effectively.

Mino Warehouse of Kita Osaka Sales Office

MOVIE

(Service for Cosmetics)

Sakata Group started operations of Mino Warehouse of Kita Osaka Sales Office in November 2019 in the first year of Reiwa as a business commemorating the 100th anniversary of its founding.

Introducing cosmetics distribution and 3PL services (movie) at Mino Warehouse of Kita Osaka Sales Office, which are state-of-the-art distribution centers.

Distribution in the cosmetics industry (professional and consumer cosmetics)

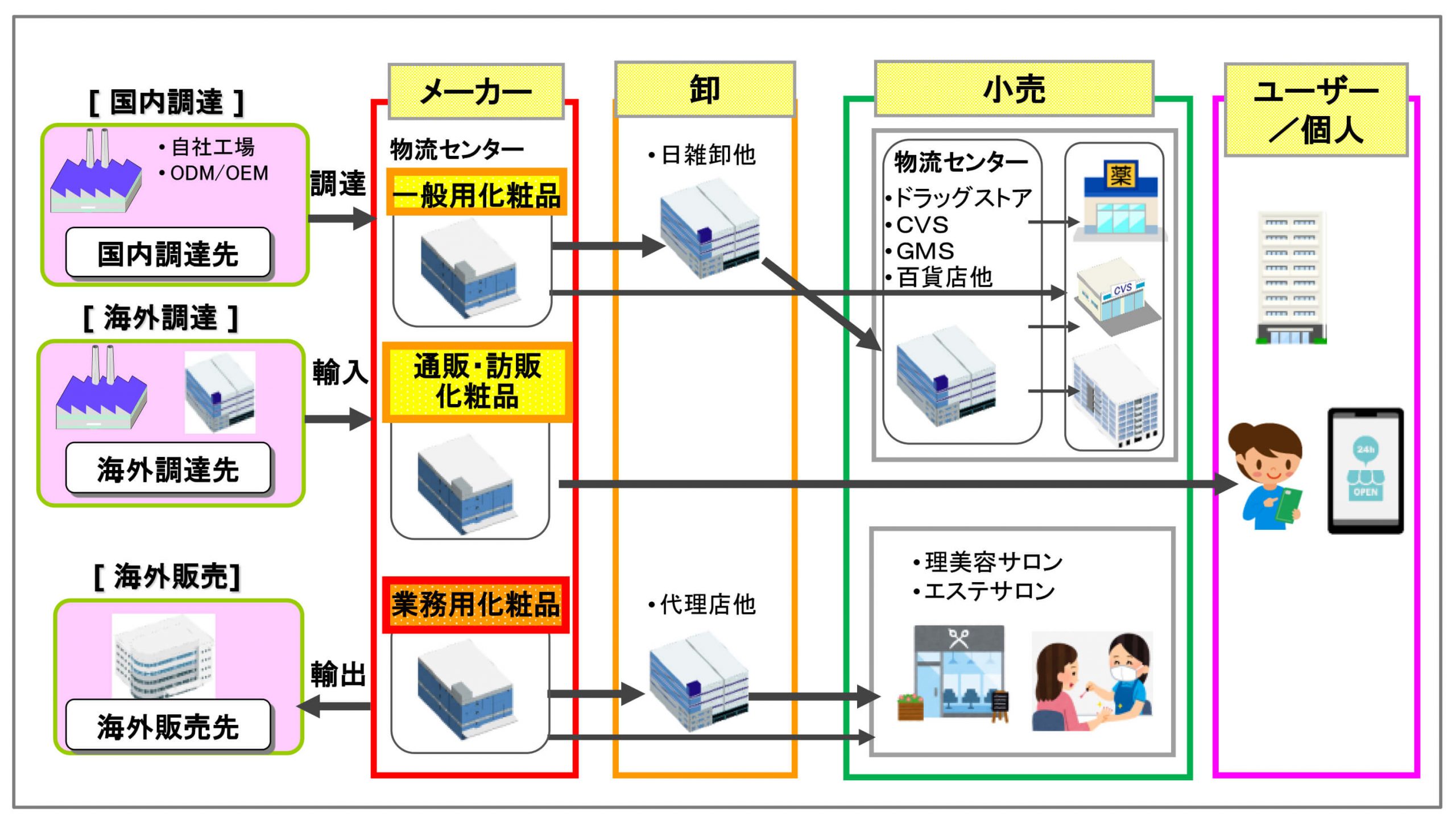

The Structure of the Cosmetics Industry

The following contents will present a concise diagram of the distribution channels of cosmetics industry.

This distribution channels recently has been changed the structure and mixed the distribution style following with the trend of growing organized retailers such as drug stores or CVS, their distribution industry used to be clearly separated into agent sales goods, general consumer goods, professional goods, route sales goods, mail/web order goods and etc. The trend of marketing imported cosmetics from overseas is on the rise as well.

Value/strength

Value/strength

The followings are listed the problems and the request matters in the cosmetics industry summarized originally by our company.

1-1.The problems about a physical distribution (example)

- The piece selling case (example: one hair color), you have to make “various kind small-quantity” shipping efficiently.

- As there are many high value items, you are requested by the customers to make the “0″ error ratio for their distribution.

- Since the goods are shipping by inner box, you have to be careful for handling not to make any scratch to the exterior (shrink wrapping and etc.). (Such a scratch will make a goods to be a second grade items)

- Because of large-volume rollout of new products is performed every season, the fluctuation of distribution becomes very big.

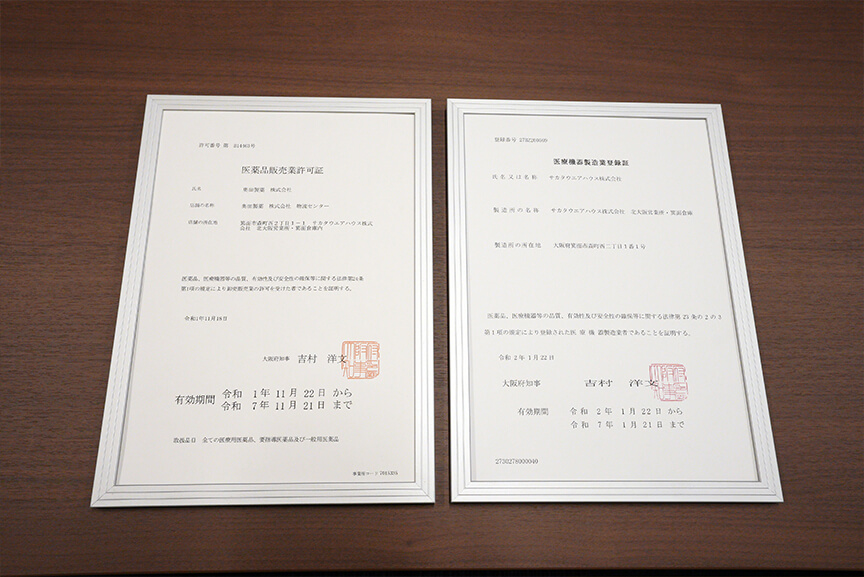

- When a company imports cosmetics from overseas and sells them in Japan, manufacturing authorization (storage, display, packaging) are required by the revision of the Pharmaceutical Affairs Law, in order to distribute goods in Japan.

1-2.Requirements from the owner of goods (examples)

- It is necessary to build a logistics system that can respond to the expansion of products handled and the addition of distribution channels and business categories (online shopping, etc.).

- Improving logistics service for the customers and restructuring logistics for the future sales increasing.

- I want to build a framework which can provide effective operation (saving the logistics cost) to high-mix low-volume shipments.

- In addition to the above, I also want to build a system for keeping the high quality of shipping without any warehouse expert.

- In order to eliminate the damage claims from customers (loss of sales opportunities), I want to build a system for handling products with care.

- I want to build the flexible operating system for the adjustment to extend the man power at the big fluctuation of the shipping such as new products rollout.

- We want Sakata to arrange a domestic warehouse possessing a Manufacturing Permission (packaging, display, storage) of the Pharmaceutical Affairs Law. or domestic warehouse which will be able to obtain the permission.

- Some products are designated as a hazardous material under the Fire Defense Law or require temperature control, and we would like you to propose a warehouse that can properly manage these products according to their characteristics.

Sakata warehouse’s 3PL service will

solve these problems!

1.Creating a support scheme (system) for high-mix low-volume shipment

We have standardized and streamlined our shipping operations with the “Standard Package Label System”, which integrates shipping labels and transportation labels.

We have also improved productivity by introducing the Voice Picking System (VPS) for piece picking operations. (photo on the left) The “Standard Package Label System” can also be used for parcel delivery labels, making it possible to respond to BtoC logistics.

2.Build a system that can maintain a high delivery accuracy (Error Ratio : under 20 ppm)

We have introduced a system to manage shipment operations by piece by linking the voice picking system (VPS) with the delivery inspection system. In addition, we have introduced a delivery confirmation system to check the number of units by carrier and barcode inspection of products in case units, and have improved the accuracy of shipments by checking the shelf stock of only the items to be shipped on the same day before delivering the shipped products.

3.Performed the well-adjustment of the wave motion of the amount of recourses.

With the shelf location management of piece-picking inventory and the piece-packaging volume calculation and packing cardboard instruction functions of the “Standard Packing Label System”, we were able to standardize piece-picking operations, expand shipping capacity by temporarily increasing the number of personnel during the busy season, and shorten working hours.

In addition, by taking advantage of our many years of logistics know-how in the cosmetics industry, we have created storage and work layouts for each product category according to the frequency of shipments to further improve work productivity.

4.Proposal for a warehouse to obtain a Manufacturing Permission (packaging, display, storage) of the Pharmaceutical Affairs Law

By having our own Responsible Engineer for the Pharmaceutical Affairs Law, we are able to obtain manufacturing licenses for cosmetics and quasi-drugs.

We also have warehouses in the Kanto and Kansai regions that have already obtained manufacturing licenses. At our warehouses, we can provide various consultations such as inspection of imported cosmetics based on the Pharmaceutical Affairs Law, affixing of pharmaceutical labels, creation of set products, and creation of manufacturing records.

5.Proposals for warehouses for dangerous goods under the Fire Service Act and for temperature-controlled warehouses

We have a dangerous goods warehouse on the premises of our warehouse, or we can use a nearby dangerous goods warehouse that is affiliated with us. We can also install temperature-controlled storage in the warehouse and propose storage and inventory management functions that correspond to the various product characteristics required for cosmetics distribution.

1.Informationization/mechanization of picking operations (introduction of VPS, etc.) to support frequent small-lot shipments and BtoC logistics

By standardizing the main operations related to warehousing and shipping through systemization using WMS and business support tools, and by having part-time workers carry out these operations, we have been able to control the operating costs (labor costs) associated with high-frequency small-lot shipping for BtoB and BtoC logistics and realize high-quality high-frequency small-lot logistics.

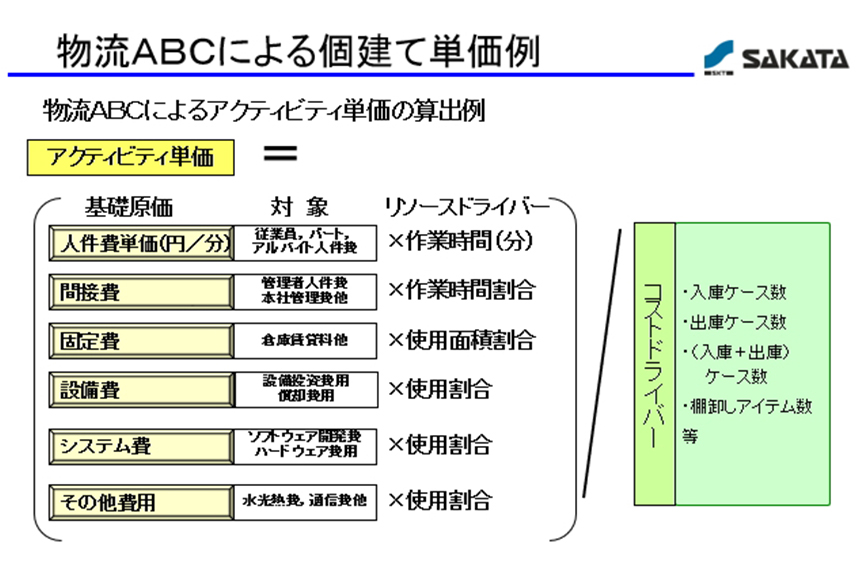

2.Variable logistics costs through unit pricing linked to shipment volume (shipment value)

Based on the piece-picking operation using the Voice Picking System (VPS), we have achieved cost control by converting logistics costs into variable costs by setting shipping operation costs based on the number of packages shipped, which is disregarded per piece per package.

3.Eliminates delays in delivery during volume surges (peaks)

Even in the event of a surge in the volume of goods shipped that is several times greater than the normal shipment volume, we were able to improve workability and productivity by establishing a system (IT) that allows us to easily increase the number of personnel and effectively allocate products (e.g., location settings), thereby eliminating late-night work and delays in delivery, and maintaining and improving our services.

4.Imported products can be distributed in Japan without going through domestic factories.

Until now, we had to receive imported cosmetics at our main factory, which has a manufacturing license under the Pharmaceutical Affairs Law, and move them to the warehouse after manufacturing and shipping decisions. This has reduced the pressure on the factory’s manufacturing space due to seasonal fluctuations.

5.Hazardous goods warehouse and temperature-controlled warehouse to reduce transportation costs.

By storing dangerous goods in the dangerous goods warehouse attached to our warehouse site or in a nearby affiliated dangerous goods warehouse, and by storing goods that require temperature control in temperature-controlled warehouses, we have reduced the costs (freight, loading and unloading fees, etc.) associated with moving goods to dedicated warehouses that were previously incurred.

Service Q&A

Service Q&A

The following is a list of frequently asked questions and answers about our 3PL service in the cosmetics industry.

Improvements in logistics consulting analysis by (paid), posing challenges, from suggestions for improvement, Sakata warehouse is developing a one stop service until ( 3PL warehousing services) of actual business practice. Improvements in logistics, distribution system reconstruction, such as cost control (reduction), but about logistics, please feel free to contact us.

We propose a system based on logistics management and EDI integration with shipping labels and shipping company, such as the implementation and operation of support systems shipped large-scale and other (DPS) Digital Picking System, according cart picking system with handy wireless terminals, and the inspection system POS, Voice Picking System (VPS), the “Standard Packing Label System” standard of our own, shipping labels, exporting the know-how of our actual business improvement towards your logistics. The smooth start-up support at the time of introducing the system, we can help you to take advantage of these systems as well. *2

*2.Support costs introduction systems, support contracts, and system cost is required separately.

Centralized management of inventory by our distribution center, we will provide the delivery service corresponding to wholesalers requirement such as separate delivery to each Sales/Salon for shipping, packaging, the consolidated delivery to the sales office and etc. Furthermore, using our own system we will manage the whole logistics procedure – inventory with high precision performance of the bar code system, accurate sorting and separate delivery for each Sales/Salon and etc.

We take over manufacturing industry and domestic distribution center business by package, using our cosmetics and unregulated drug [manufacturers license] acquisition warehouse by the Pharmaceutical Affairs Law. Well versed our staff both in charge of logistics and the Pharmaceutical Affairs Law, carries out products management business of your company.

Sakata warehouse, by presenting logistics data over a period of time (receiving data , shipping data, stock keeping data and etc.) from the customers, we will analyze these data and change the fixed cost to floating cost of unit price contract for storage fees, handling fees in warehouse, picking fees, packing fee and etc. *3

*3.Setting the unit price with minimum price, we will charge the minimum price in case of total charge goes below this setting charge and the fixed charges will remain for some part.

Sakata group, we tie up with route delivery trucking companies and the delivery-of-goods factoring company for department stores, and issue the required each department stores delivery note and deliver the goods to them. We can also perform the delivery service for the individuals (BtoC), with the service of appointing time delivery cooperating with the trucking company, cash-on-delivery service, and payment management service related to the delivery information.

3PL service list

3PL service list

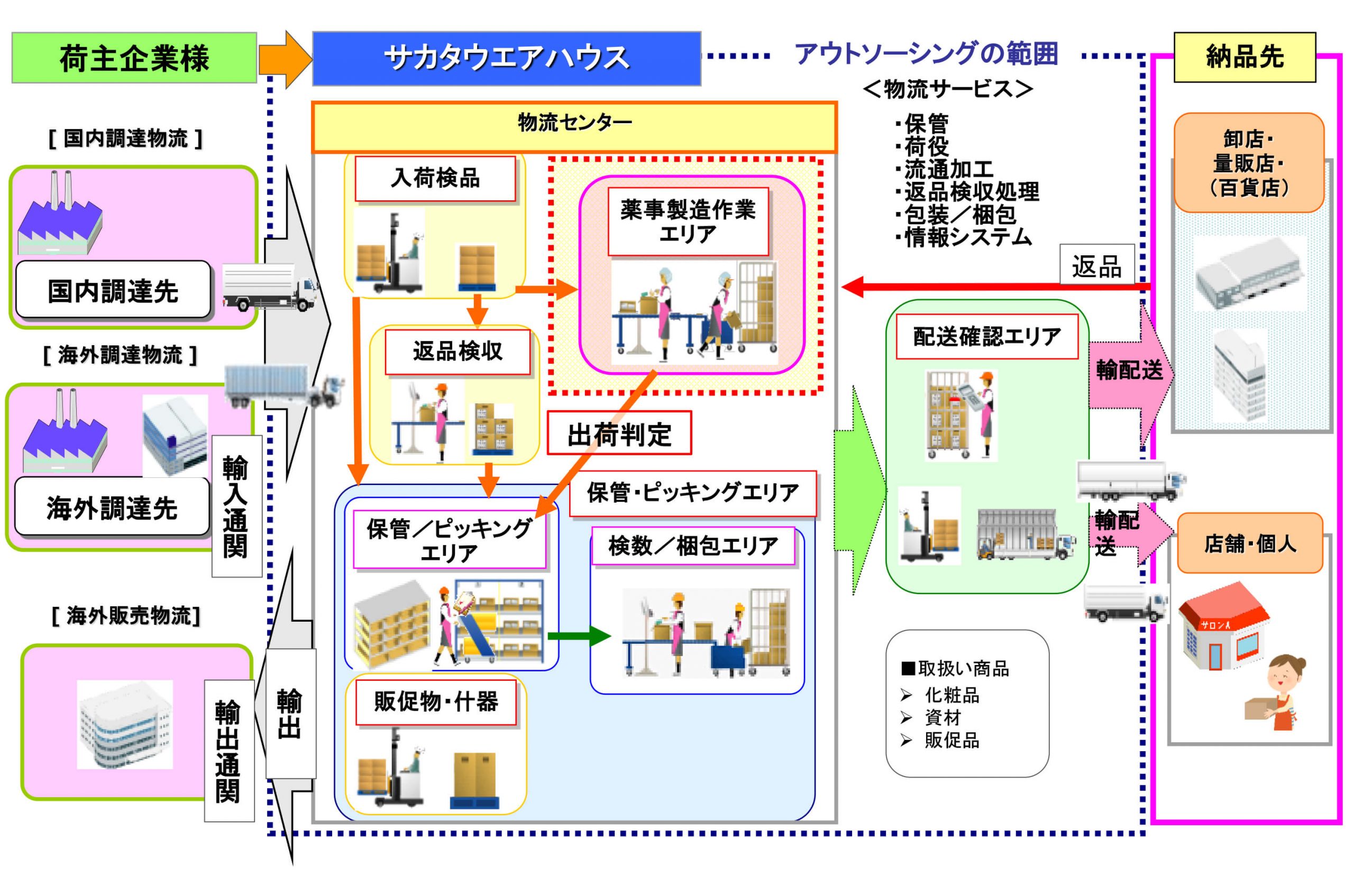

SAKATA WAREHOUSE will propose and support the realization of consistent “Supply Chain Logistics” from your domestic suppliers to end users.

We would like to introduce our 3PL service for the cosmetics industry.

Overall picture of logistics outsourcing

(cosmetic and toiletry products)

(1)3PL Services

1.Inventory Management (Stock Keeping)

Using WMS (Warehouse Management System), a system developed originally by Sakata Group which has many actual operative performances in cosmetic logistics business, we manage our inventory. It interacts with inventory input and output and also with location management, and it enables the actual and real-time stock counting in SKU (piece) and first-in first-out management of production lots.

2.Transportation and Delivery

We select and integrate the best transportation and delivery solutions (which are delivery method and selection of transportation company) using our simulation system. We can make quick response to retailers queries on delivery status exchanging parcels tracking information and information about delivery completion extracted from EDI (Electronic Data Interchange) which is operative among several transportation companies. Also, we will provide our clients with delivery status information and information about delivery completion via email for large roll out shipments of new.

3.Peace picking

We have introduced the Voice Picking System (VPS) as the standard system for piece picking to standardize and streamline operations, and the “Standard Packing Label System” that integrates shipping and delivery labels to provide total operational efficiency and high distribution quality.

4.Information system

In addition to the Warehouse Management System (WMS) proven, we can provide total operation management by our Total Logistics Management System covering whole customer’s Supply Chain from “order processing” to “delivery products to the end users”. This Total Logistics Management System is functions of the Order Management System, a system of creating tags in conjunction with a material handling machine and equipment, an inspection system in each shipping processes and Transportation Management System.

5.Quality Control

The quality control activities, as well as improvement of logistics services every day, by the improvement activities that we provide you and your customers a high quality logistics of parts per million, and the like “picking Miss zero Contest”*1 and target management system for employees.

*1 Total Quality Management (TQC) targeted Zero Miss Picking working together with customers (shippers ).

(2)Compliance with the Pharmaceutical Affairs Law / Manufacturing work

Manufacturing Permission (packaging, display, storage) of the Pharmaceutical Affairs Law

Warehouses with manufacturing licenses can perform manufacturing operations (packaging, labeling, storage) such as product appearance inspection, package replacement, and attachment of pharmaceutical labels/sealing of efficacy statements for imported cosmetics and quasi-drugs based on the Pharmaceutical Affairs Law, as well as the preparation of manufacturing records and operations/quality control by responsible engineers.

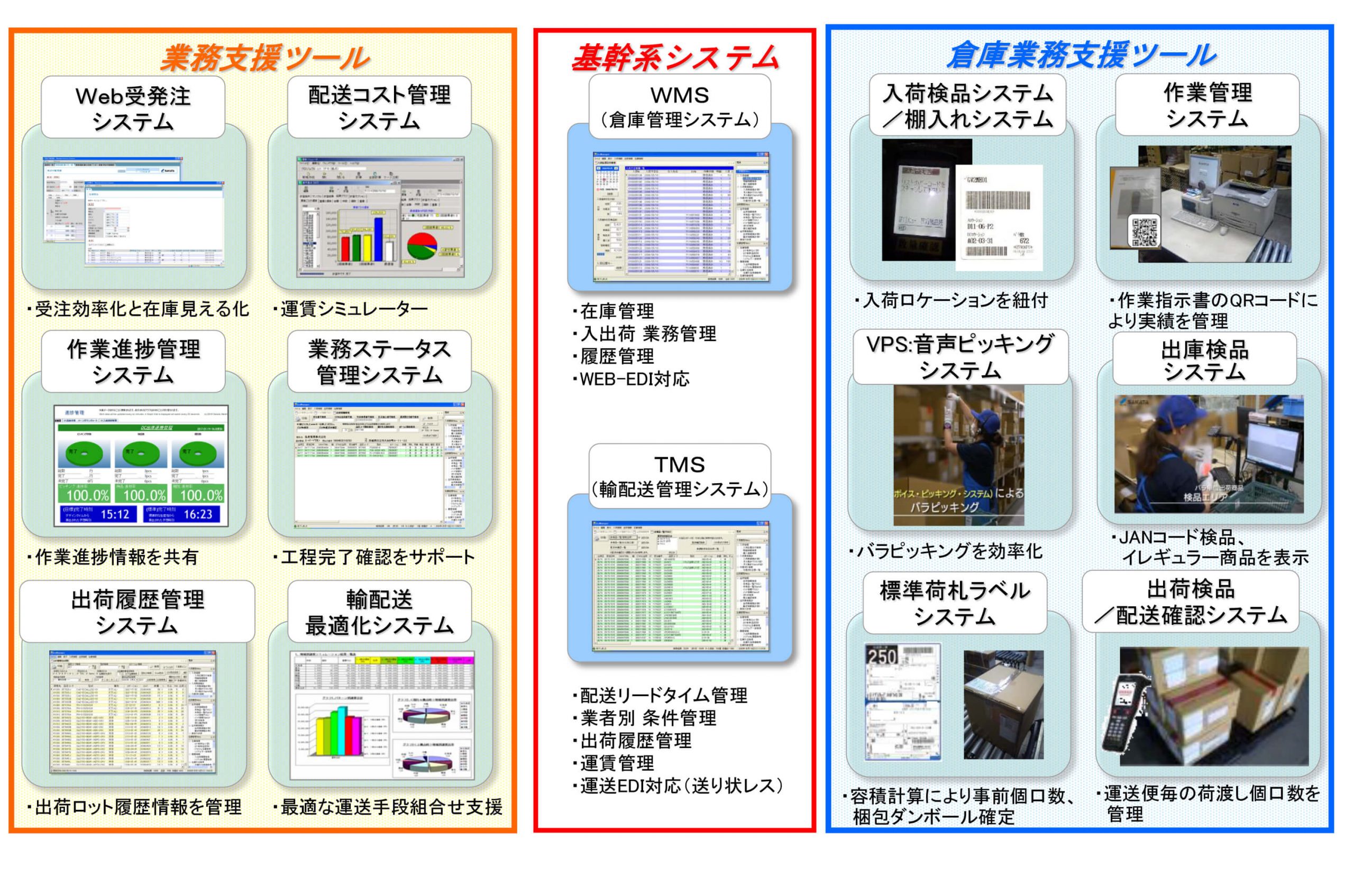

3PL Systems

3PL Systems

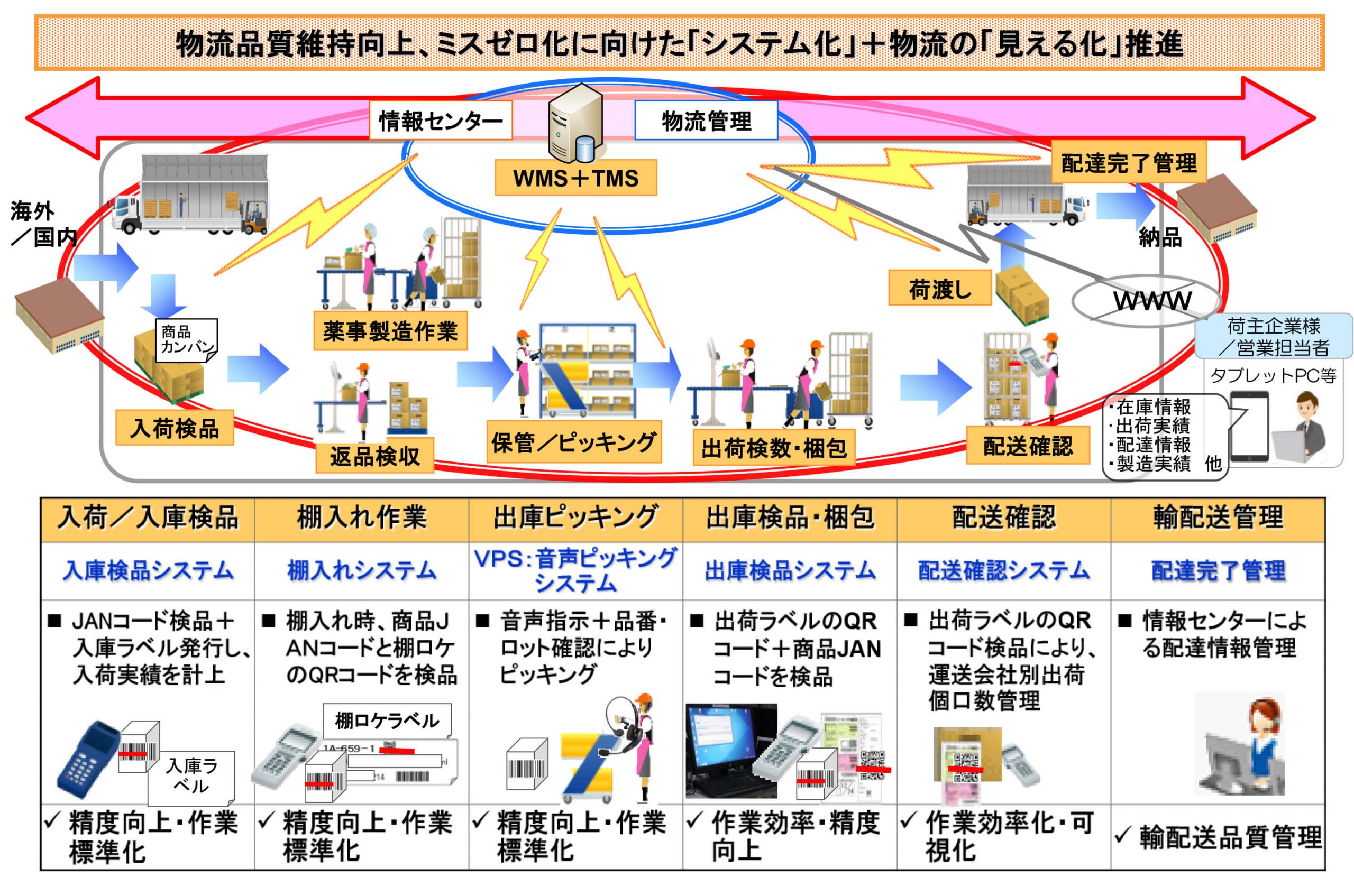

Sakata Warehouse is promoting “systemization” and “visualization” of logistics to maintain and improve the quality of logistics by standardizing and streamlining operations, and to reduce errors to zero, by linking warehouse operations support tools such as the WMS and TMS core systems, cargo labeling system, piece picking system, and shipping inspection system, with the incoming and outgoing management, inventory management, and transportation and delivery management of commercial and general cosmetics.

We also provide high quality and accurate information services (fulfillment services) to our customers by using business support tools such as web-based ordering systems and shipping history management systems.

Overall picture of the 3PL logistics system (“standardization + efficiency + visualization” promotion)

System Introduction

Warehouse /DC list

Warehouse /DC list

Sakata Warehouse has distribution centers in the Kansai, Chubu, and Kanto regions, providing warehouse services and distribution center functions in compliance with the Pharmaceutical and Medical Devices Act for cosmetics, quasi-drugs, and medical devices, which are frequently requested by our customers.

We also provide BCP-compliant logistics services through the coordination/networking of our bases.

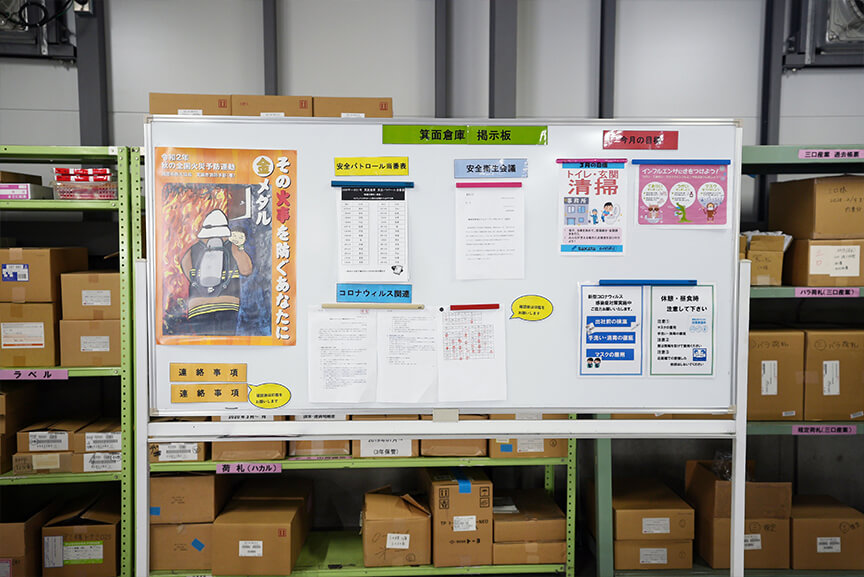

DC Quality Control

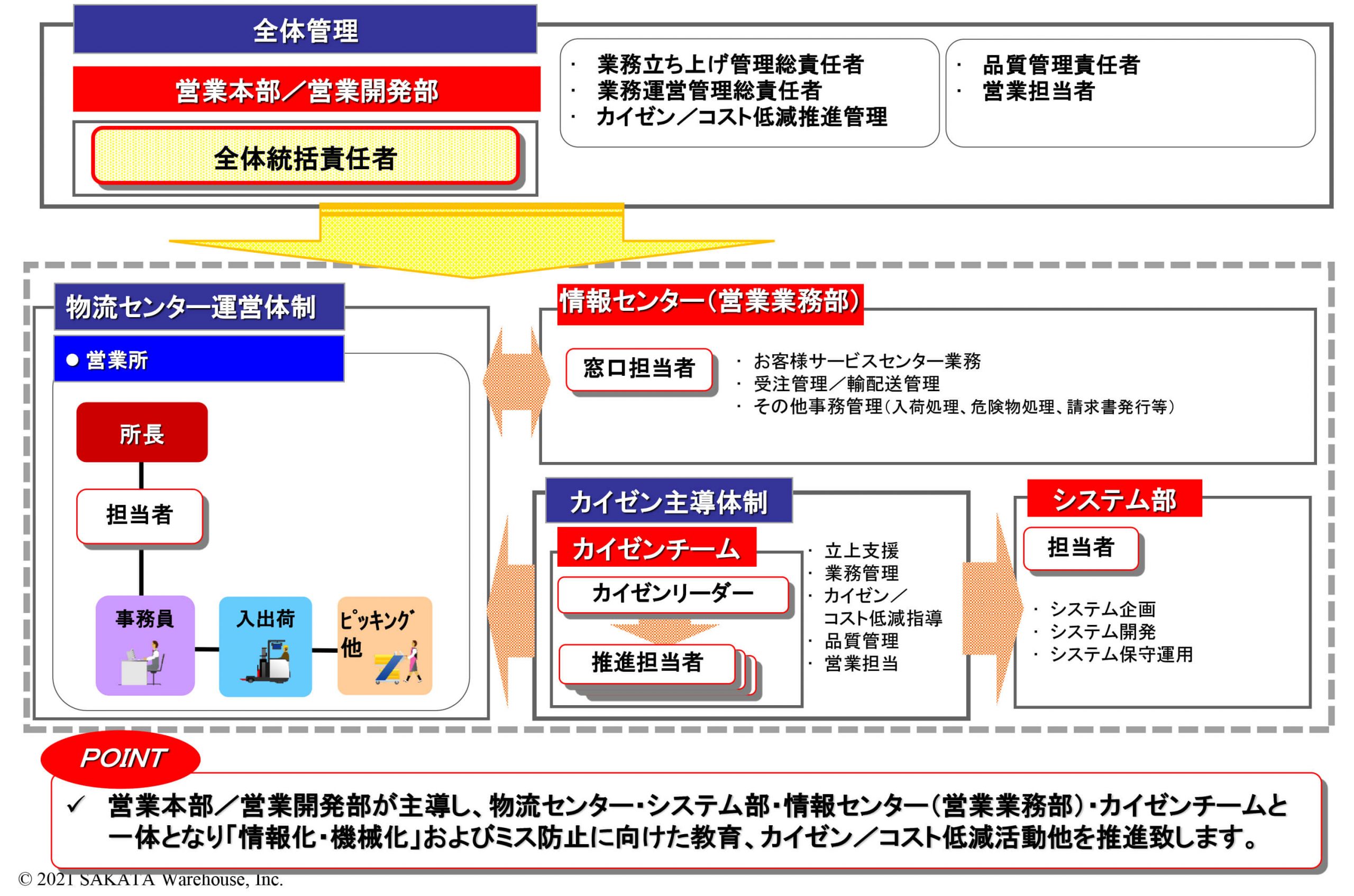

DC Quality Control

Sakata Warehouse has set up a department to implement company-wide quality control, and is working to maintain and improve total logistics quality by providing education, guidance, and support for 5S methodology and Kaizen at each sales office/logistics center, as well as coordination and collaboration among related departments.

In addition, we hold regular meetings with our customers to analyze the causes of accidents and complaints, take countermeasures, and report on Kaizen activities to enhance the relationship of trust with our customers, promote internal and external communication, and implement stable quality control.

Value/strength

Value/strength Service Q&A

Service Q&A 3PL service list

3PL service list 3PL System

3PL System Warehouse /DC list

Warehouse /DC list DC Quality Control

DC Quality Control