Warehouse Management System (WMS)

– Warehouse management system linked with 3PL service that realizes high precision and high quality for high-frequency small-lot logistics –

Sakata Warehouse uses a warehouse management system (WMS) and a transportation and distribution management system (TMS) based on its extensive experience and experience in the operation and management of multi-frequency small-lot logistics/distribution centers for cosmetics, toiletries, electronic components, electrical equipment, OTC pharmaceuticals, medical equipment, household goods and health foods.

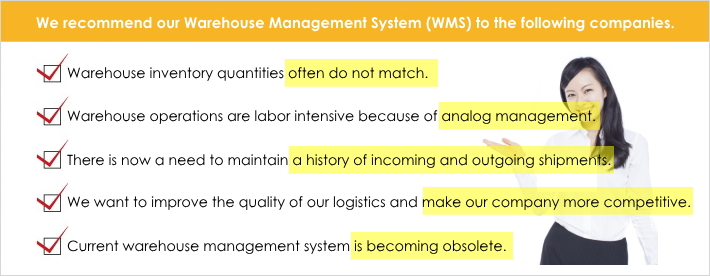

The Sakata Warehouse Management System (WMS) solves all of these problems.

1. Features of the Sakata Warehouse Management System (WMS)

The Sakata Warehouse Management System (WMS) addresses the following points that companies need and are concerned about in their logistics operations.

(1) Support for business operation management at multiple locations and warehouses

- Supports the inventory management of multiple logistics bases, multiple warehouses on the same site, and multiple shipper companies required for logistics operation management, and responds to the transfer of inventory between bases and name changes

- Supports customer master registration settings when registering new shippers, as well as bulk registration using shipper master data and product master data

(2) Traceability management

- It is possible to track and manage the history of logistics information (incoming goods, inventory, and outgoing goods) using product codes and lot codes, and to support CSR at the shipper company.

- Quickly create data by specifying date ranges and customer codes, extracting relevant logistics information, and exporting CSV data.

Proven track record in managing inventory for multiple shippers

(3) Linkage with barcode inspection system and commercial software

- It is possible to link with a barcode inspection system, a tag label issuing system, a commercially available form issuing system, etc. by data transfer.

(4) Inventory management function corresponding to the management level

- Depending on the inventory classification, it supports inventory management of “good” and “defective” after warehousing inspection, inventory management based on product capacity and shape, and inventory management by lot number / expiration date.

- Individual management of the same product code is possible by linking location information with information such as product code, product lot, and warehousing date.

- Inventory management by storage lot such as pallet / case unit inventory, bulk / box unit inventory, and inventory allocation management by customer of the same product are possible.

(5) Billing management by customer

- Supports unit price master registration management of storage fees (three-term system, tsubo rental), cargo handling fees, and incidental work fees for each customer, and creation of billing data for each customer on a monthly closing date.

- With the CSV data output function of billing data, monthly billing / sales management for each customer using Excel etc. and aggregation management for each sales office are possible. Depending on the inventory classification, it supports inventory management of “good” / “defective” after warehousing inspection, inventory management based on the capacity and shape of the product, and inventory management based on lot number / expiration date.

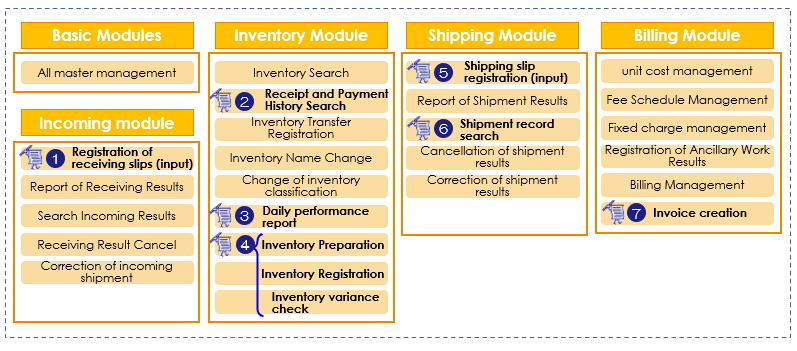

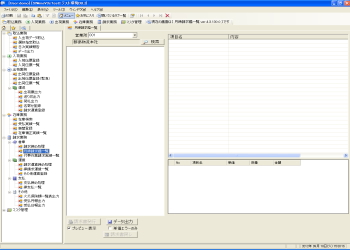

Main functions of the WMS module

This is a list of functions of Sakata Warehouse’s WMS.

2. Functions of the Sakata Warehouse Management System (WMS)

The Sakata Warehouse Management System (WMS) has the following seven main functions.

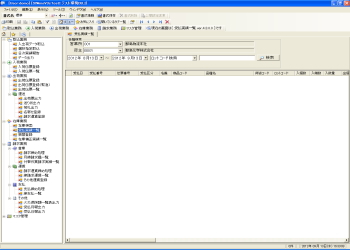

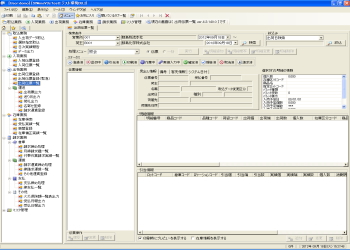

| (1) Registration of receiving slips (input) | (2) Receipt and Payment History Search |

|---|---|

|

|

| You can register actual stock (arrival date, name, lot, inventory class). The location information stored in the warehouse is also registered. | You can search the history of incoming and outgoing shipments by specifying the period, product code, location number, and slip number. The search results can be saved as a CSV file or pasted into Excel. |

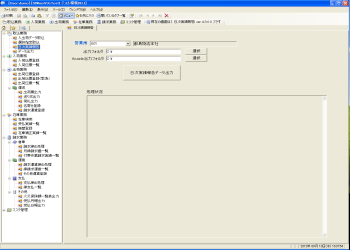

| (3) Daily performance report | (4) Inventory preparation, inventory registration, inventory variance check |

|

|

| You can create data (CSV format) on the results of incoming shipments, outgoing shipments, and inventory results. This data can be used as daily performance report data to be sent to the shipper company or person in charge. | Check the inventory difference by outputting the inventory table of the specified shipper, name, sales office, and warehouse, entering the inventory result, and registering the actual inventory number in the system. |

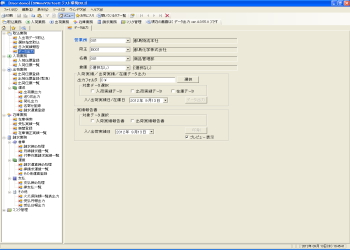

| (5) Shipping slip registration (input) | (6) Shipment record search |

|

|

| You can register the shipping record by entering the shipping instruction sheet. You can select from the inventory list and withdraw the inventory. | From the finalized shipping slip data, it is possible to search for shipping slip data using the shipping date, destination code, and product code as keys. |

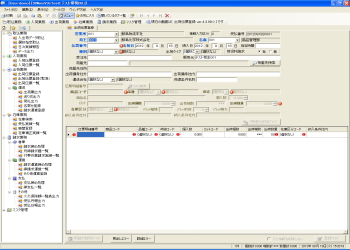

| (7) Invoice creation | |

|

|

| We will process the billing for each billing destination, and issue the billing details of the registered storage, cargo handling, and individual work charges related to the billing destination, and issue the invoice (our form). |

3. User’s Voice

(1) Customer Comments

|

|

(2) System Partner’s Voice

|

|

With the introduction of Sakata Warehouse’s WMS for small and medium-sized logistics companies, we have been able to dramatically improve inventory accuracy and eliminate errors during inventory checks, which has earned us high praise and trust from our shippers. In addition, we have been able to improve workability and productivity in the warehouse, which in turn has contributed to cost reduction. There was no big confusion in the launch, and I think it was really good to take the plunge and introduce it.

With the introduction of Sakata Warehouse’s WMS for small and medium-sized logistics companies, we have been able to dramatically improve inventory accuracy and eliminate errors during inventory checks, which has earned us high praise and trust from our shippers. In addition, we have been able to improve workability and productivity in the warehouse, which in turn has contributed to cost reduction. There was no big confusion in the launch, and I think it was really good to take the plunge and introduce it. In the field of logistics and distribution, the WMS is the core system, so ease of use is very important. Sakata Warehouse’s WMS is a system that utilizes our own experience in the field and reflects the needs of the field, so we can provide it to our customers with confidence. We will continue to work closely with our partners in order to provide a good system to our customers.

In the field of logistics and distribution, the WMS is the core system, so ease of use is very important. Sakata Warehouse’s WMS is a system that utilizes our own experience in the field and reflects the needs of the field, so we can provide it to our customers with confidence. We will continue to work closely with our partners in order to provide a good system to our customers.