Dedicated website for Minoh Warehouse

Introduction of Minoh Warehouse of Kita Osaka Sales Office

Minoh Warehouse of

Kita Osaka Sales Office

MOVIE

Cosmetics logistics

The Sakata Group started operations at the Minoh Warehouse of Kita Osaka Sales Office in November 2019 as part of its 100th anniversary project.

This site introduces the cosmetics industry and 3PL services at the Minoh Warehouse of Kita Osaka Sales Office, which are state-of-the-art distribution centers.

It is about 3 minutes away from the “Minoh Todoromi Interchange” on the Shin-Meishin Expressway, and about 30 minutes to the center of Osaka City via Minoh Green Road. With convenient access to major cities, it is an excellent location to provide stable logistics services.

The warehouse is equipped with air-conditioned distribution processing areas (a manufacturing location under the Pharmaceutical Affairs Law) on each floor, and material handling equipment that automatically sorts out shipping luggage according to the type of transportation company. Customers, related parties, and our employees We aim to practice “Work Style Reform”.

Facility Overview

Facility Overview

Facility Overview

Facility Overview

| Name | Sakata Warehouse, Inc. Minoh Warehouse of Kita Osaka Sales Office |

|---|---|

| Location | 2-1-1, Morimachi-Nishi, Minoh-City, Osaka-Prefecture |

| Structure | Steel structure, sandwich panel / ALC board |

| Site Area | About 4,500 tsubo(14,900 m²) |

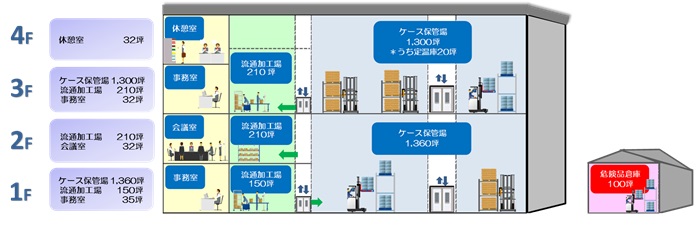

| Total floor area | Four-story, One-class warehouse: about 4,820 tsubo(15,906 m²) *Including Phase II construction expansion Single-story hazardous materials warehouse: about 100 tsubo(330 m²) |

| Ceiling height | Effective height of 6.6 m to 7.3 m or more (case storage area) |

| Floor load | 1.5 tons (0.8 tons in the 2nd floor distribution processing area only) /m² |

| Facility | Two elevators, vertical conveyors, automatic sorting transfer line, truck reservation reception system, temperature-controlled storage (20℃/in case storage area),air conditioning (distribution processing area), emergency power supply, wireless LAN in all buildings |

| Acquisition and permission, etc. | Cosmetics, quasi-drugs, medical equipment manufacturing license (packing, labeling, storage) Facility certified under the Law for Total Logistics Efficiency (until 2023). Facility certified under the Green Management Certification. |

| Completion | October 2019 |

Features

Features

Features

Features“Disaster-resistant” logistics facility

- There are no active faults in the vicinity, and the site is located on an inland plateau 250m above sea level, so there is no tsunami damage.

- The warehouse is equipped with an emergency power supply system to maintain information management and cargo handling equipment functions in the event of a power failure.

“Environmentally and people-friendly” logistics facility

- It is a facility with functions suitable for promoting “Raku-raku soko-The new combination logistics-”

- We have installed LED lighting in all buildings to reduce CO₂ emissions and save energy.

- We will create an environment where employees and drivers can work comfortably as much as possible, and strive to eliminate labor shortages and driver shortages.

Logistics facilities that “create added value”

- In addition to measures such as dustproof, insectproof, and birdproof in the warehouse, we will also introduce mechanical security and monitor cameras to thoroughly manage hygiene and security.

- The air-conditioned distribution processing plant also provides piece picking of cosmetics, pharmaceuticals, electronic parts, etc., EC logistics, manufacturing operations of the Pharmaceutical Machinery Law, and fulfillment services such as inspection, repair, and BTO.

- Cosmetics containing hazardous materials will be stored in a hazardous materials warehouse in a separate building that complies with the Fire Service Act. There is also a constant temperature storage in the warehouse building.

Facility Information

Facility Information

Facility Information

Facility Information-

Case storage area・The effective height under the beam of the case storage is 6.6m to 7.3m. By installing a heavy rack, it is possible to safely store the product at its height.

・The floor is dustproof and uses a battery-powered forklift.

・Wireless LAN is installed not only in the case storage area but also in the entire building.

・There is also a constant temperature storage that can control inventory at about 20 degrees throughout the year.

-

Distribution processing area・The ceiling height on the 1st and 2nd floors is 2.6m to 3.1m and is fully air-conditioned, making it a space close to the office.

・The ceiling height of the third floor is 4.0m and fully air-conditioned. We can provide fulfillment services that take advantage of our height.

・This is a windowless design to prevent deterioration of products due to sunlight.

・Equipped with a 200V power supply, it is easy to introduce various material handling equipment and manufacturing equipment.

-

Hazardous materials warehouse・This is a dangerous goods warehouse (in a separate building / one-story house) that complies with relevant laws and regulations such as the Fire Service Law.

・Ideal for storing cosmetics (hair sprays, perfumes, nails, etc.) containing Class 4 dangerous substances.

・Equipped with lightning protection equipment, safety is considered.

・It has an explosion-proof structure and is equipped with ABC fire extinguishers and foam fire extinguishers.

Floor Introduction

Floor Introduction

Floor Introduction

Floor Introduction

|

Case storage, 1st floor The low-floor warehouse enables efficient cargo handling, improving productivity and improving the work environment. |

|

Case storage room, 3rd floor It has a windowless design to prevent product deterioration due to sunlight and is equipped with a constant temperature storage that can manage inventory at about 20 degrees. |

|

Distribution processing area, 1st to 3rd floor The warehouse is as bright, clean and air-conditioned as the office, realizing the quality maintenance of the products it handles and a comfortable working environment. |

|

Hazardous materials warehouse By installing a dangerous goods warehouse in a separate building on the same premises, it is possible to safely and efficiently store cosmetics, etc., containing dangerous substances. |

|

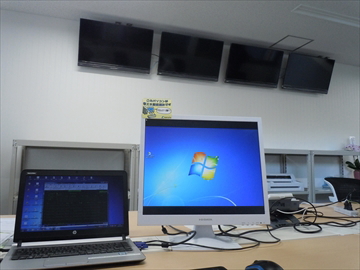

Office building, 1st floor Various information monitors are installed on the wall of the office, and a dedicated cargo reception is also provided. |

|

Office building, 2nd floor We have a meeting space for communication between the company and outside. |

|

Office building, 3rd floor We have set up a spare office in consideration of business expansion and response in the event of a disaster. |

|

Office building, 4th floor Clean toilets, changing rooms, rest rooms, etc. are provided to make the environment friendly to workers. |

Equipment and service introduction

Equipment and service introduction

Equipment and service introduction

Equipment and service introduction

|

Sorting transfer line The distribution processing areas on each floor transport the shipping boxes that have been piece-picked, inspected, and packed, and automatically sort them by shipping company using the tag BC. |

|

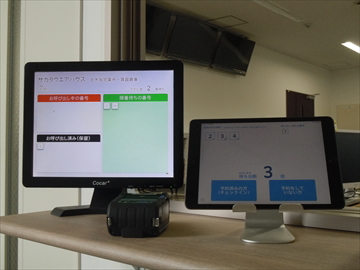

Truck reservation reception system We will ask truck drivers to register at “LINE” and notify them of their turn to eliminate waiting time in the warehouse. |

Initiatives

Initiatives

Initiatives

InitiativesTo achieve the so-called “Work Style Reform”, we will introduce material handling equipment and information systems that contribute to reducing the workload, improving the work environment, and improving work quality.

We practice 5S of rearranging, tidying, cleaning, cleanliness, and discipline. We decide place to put thing to use in warehouse and do not put unnecessary thing, and everybody strives to maintain a clean environment by regular cleaning.

Time and space to refresh is also important for those working in the warehouse. There is also a rest room with BGM and WiFi facilities, a Japanese-style room with tatami floors, and an outdoor space with consideration for planting.

Access

Access

Access

AccessSurrounding map

Transportation

[How to come by car] :

・About 2.2km from the Minoh Todoromi IC of Shin-Meishin Expressway.

・About 2.3km from the Minoh Toll Road “Mino Green Road” exit.

(Both are about 4 minutes by car)

[How to come by railway] :

・About 15 minutes by car from Mino Kayano Station on Osaka Metro Midosuji Line (direct) / Kita-Osaka Kyuko Line.

Facility Overview

Facility Overview Features

Features Facility Information

Facility Information Floor Introduction

Floor Introduction Equipment and service introduction

Equipment and service introduction Initiatives

Initiatives Access

Access