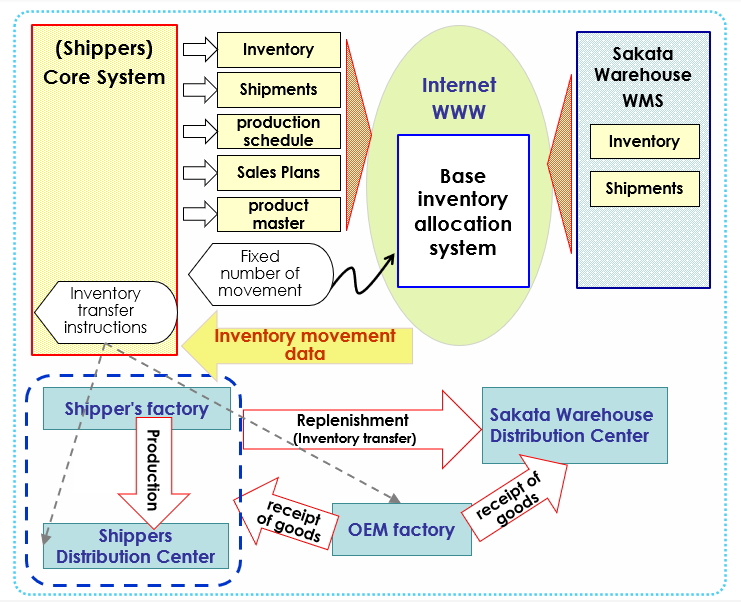

Base inventory allocation system

– A system that supports inventory management at multiple locations by linking to 3PL services –

The Sakata Group provides a multi-site inventory management support service for shippers by linking our self-developed “Base inventory allocation system” with our 3PL service.

1. About the Base inventory allocation system

| The following is a summary of the features of the “Base inventory allocation system” provided by the Information Center and our Systems Department. |

(1) Supports inventory distribution between bases based on past shipment results, sales plans, production plans, and inventory results

- It is possible to set the minimum number of months of inventory based on past shipment results, sales plans, production plans, and inventory results, and support replenishment of production inventory to bases and creation of inventory transfer plans between bases.

(2) Inventory distribution data can be created by calculating the number of loading cases per pallet for charter vehicles.

- By replacing the data of movement to the base with the number of pallets, it is possible to calculate the number of pallets loaded on a truck and confirm the number of trucks required.

(3) Inventory distribution data can be shared on the Web and managed by participating in multiple departments.

- By displaying a tabular screen on the Web and importing CSV data, it is possible to input necessary data and share inventory data in each department of production, sales, and distribution.

(4) Inventory movement plans for the following month can be created in advance, and daily movement volume adjustments can be set.

- Create a daily inventory movement plan for the following month based on the number of truck loads set in advance from the sales plan and production plan, and modify and set the inventory movement plan for the following day and onward by inputting and adjusting actual results.

2. Schematic diagram of the Base inventory allocation system

3. List of functions of the Base inventory allocation system

| No. | Function | Descriptiony | CLN *1 | Task cycle | Processing time |

|---|---|---|---|---|---|

| 01 | Data import (product master CSV) | Import a product master (csv) file. | batch | daily | nighttime |

| 02 | Data import (shipping results CSV) | Imports shipment record (csv) files. | batch | daily | nighttime |

| 03 | Data import (inventory CSV) | Import inventory (csv) files. | batch | daily | nighttime |

| 04 | Data import (sales plan CSV) | Import sales plan (csv) files. | batch | daily | nighttime |

| 05 | Data import (production plan CSV) | Import production plan (csv) files. | batch | daily | nighttime |

| 06 | Sales Special Factors Registration Screen | Register special factors in shipment performance, such as campaign sales. (to exclude them from the shipment forecast) |

screen | monthly | as needed |

| 07 | Creation of data on percentage of shipments by product by location | The actual shipments are totaled by location, and the percentage of each location’s shipments is calculated for each product. | batch | monthly | nighttime |

| 08 | Creation of sales plan data by location | Based on the percentage of shipments by location by product, a sales plan is prepared by location. | batch | monthly | nighttime |

| 09 | Sales Plan Data Revision Screen by Location | Revise the sales plan by location. | screen | monthly | as needed |

| 10 | Product movement planning (Month-end inventory forecasting & transfer planning) |

Based on the current inventory, sales plan and production plan by location, the inventory at the end of the following month is estimated, and the overall number of product transfer for the following month is estimated. The result is allocated to the number of truckloads, and a daily product transfer plan is created. |

batch | monthly | nighttime |

| 11 | Create current inventory data | Create the current inventory, the number of months of inventory, and the arrival schedule for each product by location. | batch | daily | nighttime |

| 12 | Creation of sales achievement rate data | Create sales plan achievement rate data by product by location. | batch | daily | nighttime |

| 13 | Current Inventory / Product Movement Plan / Sales Achievement Percentage Confirmation and Revision Screen | Batch checks the current inventory, product transfer plan, and sales achievement rate for each product. It also modifies the product transfer plan. |

screen | daily | as needed |

| 14 | Product transfer request data confirmation screen | Correct the data for the product transfer request. | screen | daily | as needed |

| 15 | Creation of data for product transfer requests | Create product transfer request data. | batch | daily | Ex.15:30 |

| 16 | Product Master Maintenance Screen | Maintain product attributes. | screen | daily | as needed |

*1.CLN: Cassification