Logistics Consulting

we can support your company’s logistics improvement with our warehouse and 3PL services.

At Sakata Warehouse, we propose logistics improvements in cooperation with our warehousing and 3PL services to companies in the following industries:

(1) cosmetics, (2) electrical, industrial, and medical equipment, (3) pharmaceuticals, and toiletries, based on our know-how of high precision and high quality logistics services cultivated through high-mix, low-volume logistics.

Common requests for 3PL service

There is an urgent need to improve the quality and accuracy of logistics due to customer demands.

We want to be more cost competitive than our competitors by reducing our logistics costs.

With the logistics system unable to keep up with the increasing volume of goods, we don’t know where to start.

We want to improve the efficiency of the entire logistics process by reviewing our logistics operations.

We want to achieve optimal inventory segregation and management of replenishment and order quantities by restructuring the allocation of bases.

We want to achieve accurate and appropriate inventory management by implementing a logistics system.

Proposals for improving logistics in cooperation with our warehouse and 3PL services

Improvement of the bases arrangement

Improvement of the bases arrangement

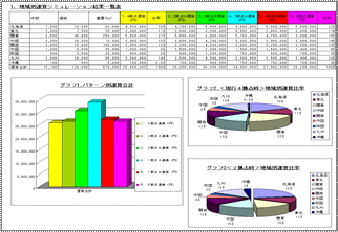

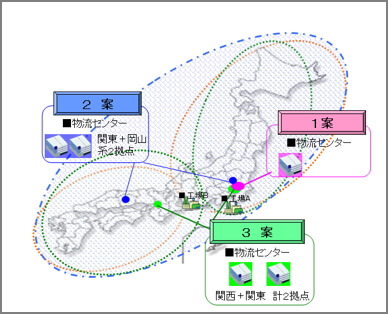

By improving logistics in a multiple base, we can propose the best arrangement of bases

Carring out the simulation of multiple base arrangement patterns, we evaluate and analyze following points about each base.

(1)Transportation/Delivery cost

(2)Base management cost

(3)Volume of inventories etc.

Moreover, we propose the best arrangement of bases. The proposal is offered with following menus.

Implementation details for restructuring of logistics bases

(1)Consideration to reconstruction of a logistics base

We consider arrangement of a base to delivery to customers quickly, and to locate a depot base towards reduction of delivery cost etc.

(2)Trial calculation of base management cost at the time of new base locating

We carry out trial calculation, evaluate, and consideration of management cost at the time of new base locating, such as custody cost, loading cost, delivery cost, and system cost, etc.

(3)Reconsideration and consideration to delivery area classified by base

By Utilizing “The simulation system of carriage”etc. of our company, we carry out selection support of optimal delivery area / pattern according to base from the following points.

①Shipment lot

②Carriage cost

③Lead time

Improvement of transportation and delivery

Improvement of transportation and delivery

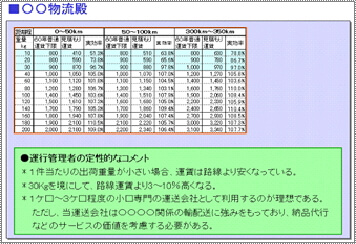

The proposal of cost reduction by date analysis about transportation

We evaluate and analyze

(1)Comparison with other companies in the same trade of transportation cost

(2)Comparison with a market price of neighboring companies of contractual coverage with a transportation company

(3)efficient management of delivery structure/management

according to a logistics base. Date analysis/Simulation about transportation makes evaliation and control of cost by a a concrete numerical value possible.

Implementation details for improving transportation and delivery

(1)Evaluate and analyze transportation costs using market trends/statistics

We compare with a market price, and evaluate or compare transportation cost with other companies in the same trade by JIL statistical materials.

(2)Consideration to transportation mode of sales logistics/ Consideration to a structure of Internal logistics (transportation between bases, as an example)

By utilizing “Simulation system of carriage”, we consider the best combination of transportation mode, and reduction of losistics cost.

(3)Consideration to a structure of logistics of procurement/logistics of salvaged

By utilizing the route simulation, we consider to introduce Milk Run, to reduce of cost by separation of a goods unit price and carriage.

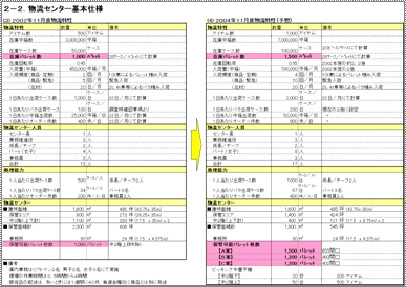

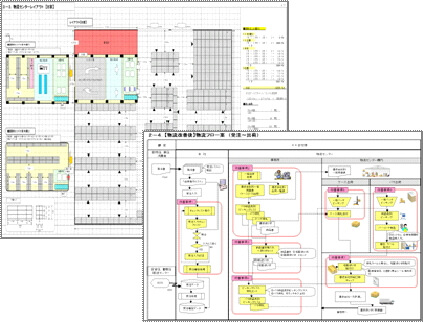

Improvement of the distribution center

Improvement of the distribution center

Review the layout and the work flow in the distribution center, we propose the way to improve your business

- Based on an actual warehouse drawing, I create palette arrangement and a shelf arrangement layout, and we calculate the number of pallets can be stored and number of items that can be placed on the shelves.

- We can create the layout proposal based on our experience in actual business in consideration of the flow line of the worker, the temporary place of incoming and outcoming goods, and the movement of forklifts.

Details of improvements made by reviewing the distribution center layout and work flow

(1)Consideration to the specification of a distribution center for throughput of the present distribution center/changing amount-resource to a future

We create a target value of per person in the present distribution center/Storage needed to a future amount-of-resources change Estimates of capacity and the number of staffs, consideration of the increase in efficiency of material handling apparatus installation, work productivity indicator.

(2)Consideration of improving the efficiency of warehouse operations

We create a workflow based on field research, and we show concrete corrective strategy from a viewpoint of “Elimination of waste, excessive unevenness”.

(3)Review and study of warehouse layout

We carry out the creation of a storage layout according to the characteristic of the current logistics, arrangement plan of shelves in picking area. and a simulation of the placement by category, size, and shipment characteristic of the goods.

Improvement of inventory

Improvement of inventory

Suggest the optimal stock based on analysisi of inventory data

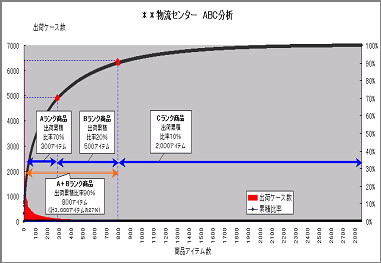

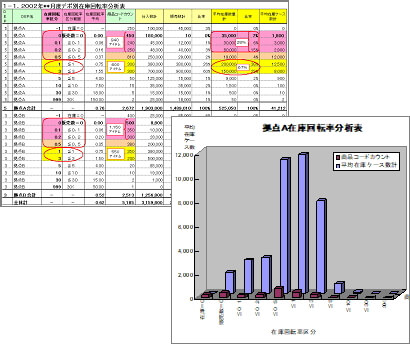

- Aggregating product, number of items, the number of inventory by Inventory turnover,and we analyze “A rank goods”, “B rank goods”, and “stay goods”.

- By considering together with the shipping and receiving daily trend, narrow products, order unit reduction, inventory reduction is possible.

Implementation details for inventory improvement

(1)Analysis of inventory turnover by product and distribution centers

We will analyze and compare different inventory turnover base dealing with the same product,

and make that ideal stock levels.

(2)Consideration to product management for efficient shipment by ABC analysis

Analysis of the product characteristics, we consider towards the introduction of efficient product placement, support system shipment, inspection system.

(ABC analysis:The method for descending order of total number of shipments by product, consider how to store and inventory levels by rank from the ratio.)

(3)Creation of a system for efficient inventory placement for different base

We adjust inventory between the sites and plan to coreate the ideal place to stock by the above data analysis.

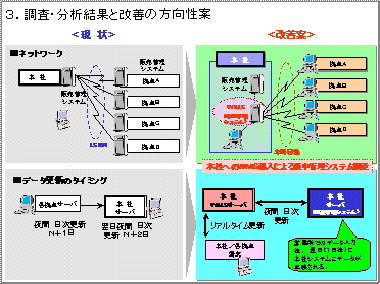

Improvement of logistics system

Improvement of logistics system

Business improvement is realized by introducing the system adapted to the business of the site.

- Our system evaluate and analyze the point that should be improved of information system of your company and the proposal to directivity according to a function.

- Our system is able to calculate expectation effect by computerization of logistics, and narrow down points of an improvement toward planning.

Implementation details for improving the distribution system

(1)Consideration to introducing an inspection system and various material handling apparatus

We perform making structure towards differentiation by improvement in throughput, logistics quality, and differentiation in respect of logistics service with the other company in the same trade, according to introducing an inspection system and material handling apparatus connected with the warehouse control system (WMS).

(2)Consideration to introducing ordered center system and automatic supplement / order system

We perform making structure towards realization of the increase in efficiency by centralization of ordering business, and automatic supplement order of the regular assortment connected with the order-receiving system.

(3)Consideration to introducing wharehouse management system(WMS) and transpartation management system(TMS)

We perform making the structure towards physical inventory management, lot/expiry data management, first-in/first-out management based on warehouse control system (WMS) introduction.

Moreover, we perform also making a base towards carriage calculation, by transportation managerial system (TMS) introduction, support to allocation of cars, introduction of cargo pursuit and lot pursuit management, delivery cost management, and trust of the delivery business from multiple owners.

Improvement of cost for distribution

Improvement of cost for distribution

Thorough support to cost control (management)

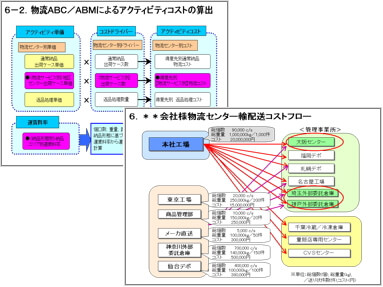

- We analyze/define the method for cost grasping towards an ABC/ABM systems configuration, and carry out cost control by a logistics cost management index.

- ABC/ABM information systematization brings about construction of structure which can grasp or manage logistics cost/sales according to 【a customer】,【logistics service】,【a form of deliver】, and logistics cost management index continuously.

Implementation details for improving distribution costs

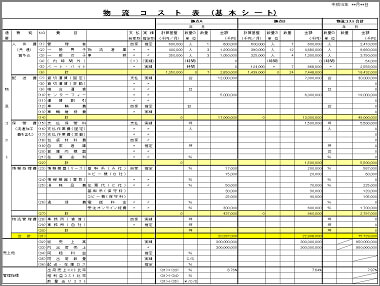

(1)Grasp or investigation of logistics cost

Based on “The manual to utilize calculation of logistics cost”, we clarify the logistics cost of your company, and perform comparison examination of a logistics cost ratio with the other company in the same trade based on grasp of the ratio for sales and statistical materials.

(2)Visualization of the cost by creation of the flowchart of cost

We classify the situation of which cost has generated in which processing into a flow chart, and select the cost target which should be improved.

(3)Production of a cost index by logistics ABC/ABM

We perform making the price list according to delivery of goods service, and the structure of cost management of business/sales division or daily logistics cost management with the client.

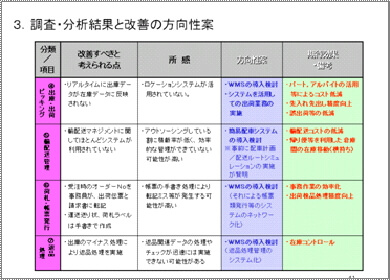

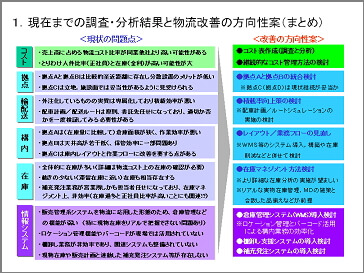

Planning of logistics improvements and verification/prediction of effects

Planning of logistics improvements and verification/prediction of effects

The remedial measures derived from each analysis and execute its PDCA

- We will form project sysytem including such as management department of physical distribution, sales department ,information system department, manufacturing department, merchandise control department and others ,

and act for gathering volition, advocate organizational reform and secretariat for reorganize of physical distribution. - It is poosible to implement study marameter to execute the medial measures and adovocate the solutions etc. based on our operational experiences.

Implementation details for improving logistics

(1)Advocating multiple directionality of implemented by result of the investigation of present data analysis

①Implement invest in plant and equipment /system in present facilities.

②Implement invest in plant and equipment /system which is connected with implementation planning of new basic system.

③Classified with essential drastic reform such as reorganization of the bases and constraction of facilities etc. , and adovocate multipul remedial measures based on result of the investigation of present data analysis.

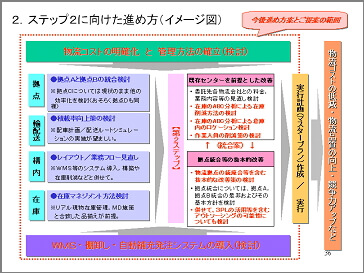

(2)Consideration/Evaluation of the remedial measures by implementation of simulation

It is need to narrow the specific theme of implementation from the remedial measures, and evaluate/consider it on accont of simulation of its cost/result for the implementation.

(3)Makaing out the action plan for the implementation of improvement

The creation and presentation of a master plan towards enforcement of the last decision remedy based on a predicted effect are performed.

※Making out the action plan will be another phase with consulting for the improvemnet of physical distribution.

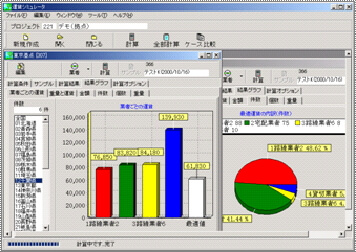

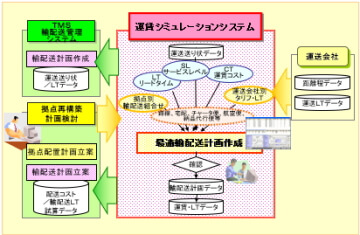

Simulation service for delivery

Simulation service for delivery

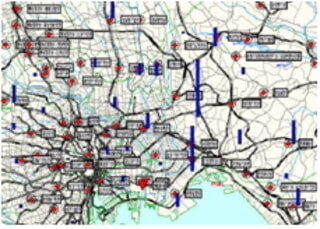

Supporting transportation and delivery strategy planning by optimal transportation and delivery combination and transportation and delivery cost simulation

Example of fare simulation result display

According to the complex condition of ①a lead time,② a service level, and ③carriage, the combination plan by optimal express companies is executed.

Based on an express company combination plan, we can execute the shipment scheduling based on the combination plan by optimal express companies, and workin with the warehouse control system(WMS).

The simulation is corresponded also to carriage calculation, such as a route, door-to-door delivery, a chartered flight, airmail, delivery on behalf freight.

By registering express companies combination according to a logistics base rearrangement pattern, we correspond to the delivery cost simulation in consideration of a lead time for delivery.

*Lead time management is managed with receipt of the data from an express company, and the data at the time of business. Service level management is managed with the data at the time of business.

The subject and the step of a solution

- You want to tackle carriage cost reduction, without dropping present delivery LT (lead time).

- You want to add a new express company and consider the best combination of the way to transport, and express companies.

- We maintain delivery LT and execute the best combination plan of express companies towards reduction of carriage cost.

- We add a new express company and execute the best combination plan of express companies for carriage and a delivery lead time by zero base thinking.

- You want to make the trial calculation of the delivery cost at the time of distribution center reconstruction, and to carry out comparison examination of the change in business cost.

- You want to make the trial calculation and consider the best area in respect of the delivery cost / lead time at the time of distribution center reconstruction.

- We can make the trial calculation of the change in delivery cost in consideration of the delivery lead time at the time of distribution center reconstruction.

- We can set up the best delivery area in respect of delivery cost / lead time at the time of distribution center reconstruction.

- You want to choose the way to delivery and transportation /an express company according to the customer’s segment, and to make the trial calculation of delivery cost.

- You want to make the trial calculation of the delivery cost at the time of recovery of a fold-up container, a box pallet, etc.

- You want to make the trial calculation of the CO2 reduction effect by concentration of the number of times of delivery / delivery lot, and joint delivery of goods.

- We can calculate the delivery cost of the best express company according to registering of a way to delivery/a express company for every customer.

- We register the contract about carriage at the time of recovery, and can calculate the delivery cost concerning recovery of a fold-up container etc. (option service)

- Based on the Ton-kilometer Law, we can make the trial calculation of the CO2 emissions at the time of delivery of goods. (option service)

Consulting Results

Consulting Results

| Company name | Industry | Contents |

|---|---|---|

| Company A | Pharmaceutical manufacturing industry | Simulation of transportation and delivery costs at the time of consolidation and abolition of distribution bases |

| Company B | Pharmaceutical wholesale business | Review of distribution strategy due to consolidation and abolition of manufacturer distribution center |

| Company C | Electrical and electronic equipment manufacturing industry | Simulation of transportation and delivery costs when contracting a new shipping company |

| Company D | Precision machinery manufacturing industry | SCM construction support including procurement, sales and distribution from overseas |

| Company E | General merchandise import business | Data analysis, on-site survey, layout creation for distribution center integration |

| Company F | Music-related wholesale business | Business improvement of distribution center by introducing system |

| Company G | Toiletries product manufacturing industry | Simulation of transportation and delivery costs at the time of consolidation and abolition of distribution bases |

| Company H | Toiletries product manufacturing industry | Creation and evaluation of cost indicators by logistics ABC in the return business |

| Company I | Cosmetics manufacturing industry | Providing advisory consulting services to logistics departments for logistics reform |

| Company J | Electrical equipment manufacturing industry | Simulation of transportation and delivery costs including expansion of distribution bases and review of transportation companies |

| Company K | Food manufacturing industry | Support for improving operational efficiency of distribution centers |

| Company L | Food manufacturing industry | Holding competitions for logistics outsourcing, support for selecting contractors, and support for system construction after contractors have been decided |

| Company M | Food manufacturing industry | Survey to reduce transportation and delivery costs |

| Company N | Food manufacturing industry | Support for building a logistics system due to an increase in physical quantity |

| Company O | Food wholesale business | Support for formulating logistics improvement plans to reduce logistics costs |

| Company P | Frozen food wholesale business | Logistics diagnosis regarding current logistics operations and delivery costs |

| Company Q | Fisheries Cooperative | Survey on new distribution center construction including automatic rack system and preparation of layout plan |

| Company R | Automotive parts manufacturing industry | Validation of current transportation and delivery methods ・ Simulation of transportation and delivery costs when contracting a new transportation company |

| Company S | Automotive parts manufacturing industry | Improving the efficiency of in-factory logistics |

| Company T | Chemical product manufacturing industry | Support for building a delivery cost calculation system |

| Company U | Medical equipment wholesale business | Formulation of distribution center reorganization plan, operation flow creation, etc. due to base integration and distribution system reconstruction |

| others | Government-affiliated research institute | Research study on strengthening corporate competitiveness and management innovation using IT in the distribution industry, etc. |

Improvement of the bases arrangement

Improvement of the bases arrangement Improvement of transportation and delivery

Improvement of transportation and delivery Improvement of the distribution center

Improvement of the distribution center Improvement of inventory

Improvement of inventory Improvement of logistics system

Improvement of logistics system Improvement of cost for distribution

Improvement of cost for distribution Planning of logistics improvements and verification/prediction of effects

Planning of logistics improvements and verification/prediction of effects Simulation service for delivery

Simulation service for delivery Consulting Results

Consulting Results